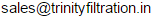

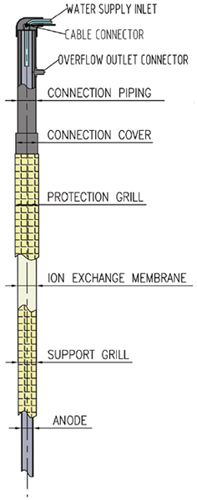

Hydrocell-T Anode cell

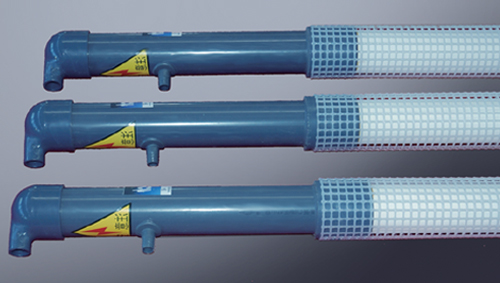

HydroCell-T cells provide the clients with maximum throw power, high efficiency and long life. Standard electrode material is 316L stainless steel seamless pipe. For special requirements, ruthenium coated titanium is used for longer life. There is outer mesh grill to protect the ion exchange membrane. The features are easy handle, power saving and low resistance. Hydrotech developed the ion exchange membrane welding technology. This update makes HydroCell –T performance and construction improved significantly.

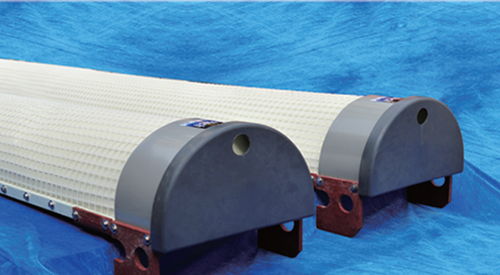

Closed Head Cells :

- Closed Head Cells can be installed below the edge of ED tank and usually be used as flushable top/bottom.

- cells to bring the paint film on floor pans and rocker panels to the desired thickness.

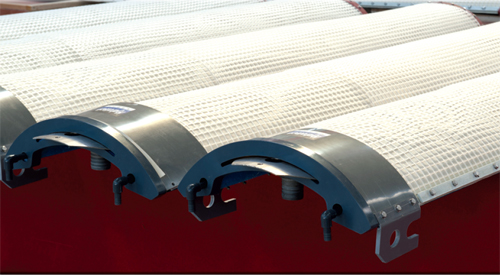

Open Head Cells :

Open Head Cells are most regular type for E-coat process. The anolyte circulation water overflows from each cell. It gives low pressure inside cells to prevent from the damage or leakages due to water circulation pressure. The special top head design provide with clean looking and easy installation.

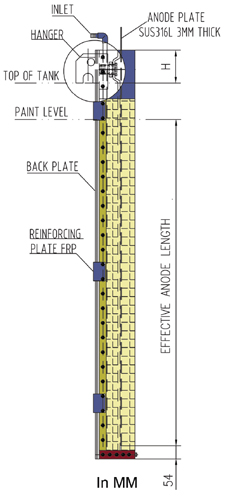

Hydrocell Hydrotech-T Anode cell :

| Type: |

Hydrocell T-15 |

Hydrocell T-20 |

| Diameter of Anode |

1.5” (48 mm (OD)) |

2” (60 mm (OD)) |

| Diameter of Cell (OD) |

3.94” (100 mm |

4.17” (106 mm) |

| Effective Area |

0.49 ft2/ ft (0.15 m2/m) |

0.63 ft2/ ft (0.19 m2/m) |

| Anolyte Circulation required per unit length |

0.1 gpm/ft (1.22 lpm/m) |

0.12 gpm/ft (1.52 lpm/m) |

| Current per unit length |

2.4 Amp/ft (8 Amp/m) |

3 Amp/ft (9.5 Amp/m) |

| Distance between cells` |

Min : 200 mm ; Max: 500 mm |

Min : 200 mm ; Max: 500 mm |

Hydrotech Hydrocell T Anode cell PDF