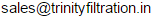

Trinity Fabricated basket strainer are designed and manufactured according to client’s application. The welded construction of the strainer, withstands various range of flow and pressure. Piping sizes available are 1.5” to 48” for 150# and 300#. The basket size is tailored to hold sufficient solid waste for enough time between cleanouts. Customized flange sizes are done to fit for exiting pipe. These strainers are installed upstream of equipment like pumps, control valves, and traps, keeping potentially corrosive or damaging debris from making its way down the line.

Features

- Welded Units designed to increase the capacity & maximum Pipe Size available

Sizes Available to hold sufficient solids for the required time between clean-outs.

- The end connections are available with Flanges or Butt Weld Connections to fit existing piping to achieve the required clean pressure drop.

- Dimensional flexibility

- Design flexibility

- Varied flow rate handling capacity

- Davit Assembly can be optional

| Size |

40 NB to 1000 NB |

| Body |

CS, MS, SS 304, SS 304L, SS 316, SS 316L. |

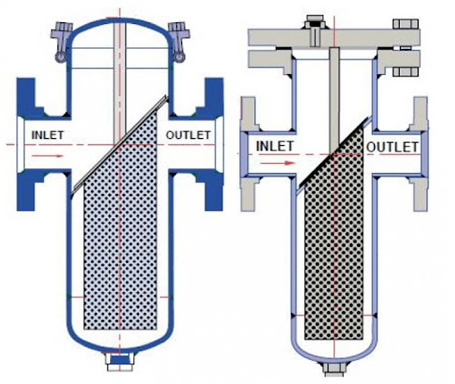

| Elements |

SS 304/L, SS 316/L. |

| End connections |

Butt welded, Flanged |

| Flow direction |

Flow Inside to Outside (FITO) |

| Design Code |

GEP (Standard), ASME (Optional) |

Applications

- Petrochemicals

- Paints

- Pharmaceuticals

- Oil

- Chemical industry

- Power industry